India’s electronics growth story will not be written by assembly alone. Embedding Design for Manufacturing into every stage of product creation is the step that can transform ambition into global competitiveness—and make India a genuine leader in electronics.

India’s push toward self-reliance in electronics is being tested across high-stakes sectors—defence, railways, energy, aerospace, and industrial systems—all of which demand hardware that is rugged, reliable, and scalable.

The old model of import dependence and assembly is giving way to something far more ambitious: electronic design for manufacturing (DFM).

No longer a peripheral practice, DFM has become the foundation for producing hardware that meets global standards while withstanding real-world operating challenges, making it indispensable to India’s rise as a serious electronics contender.

The Indian Electronics Ecosystem: Context and Imperatives

Defence, aerospace, railways, oil and gas, and renewable energy are all moving rapidly towards digitisation, creating a surge in demand for hardware that can withstand harsh conditions while delivering consistent performance. Meeting this demand requires more than incremental upgrades—it calls for a design philosophy that anticipates scale, reliability, and manufacturability from the outset.

For example, Indian Railways is undertaking the large-scale deployment of connected systems to enhance both operational efficiency and safety across its vast network. At the same time, Industrial IoT is transforming key sectors such as oil and gas, manufacturing, and energy, necessitating the use of robust gateways and intelligent edge devices to ensure reliable data processing and connectivity. Meanwhile, the consumer electronics market continues its rapid expansion, fuelling demand for innovative, high-quality products that meet evolving user expectations.

This evolution is underpinned by a national push for ‘Made in India’ electronics, not just as an assembly hub, but as a design and manufacturing powerhouse. Geopolitical shifts and supply chain disruptions have opened opportunities for India to emerge as an alternative to China. However, this also exposes vulnerabilities, especially in component sourcing, R&D infrastructure, and manufacturing maturity.

DFM: Principles and Technical Foundations

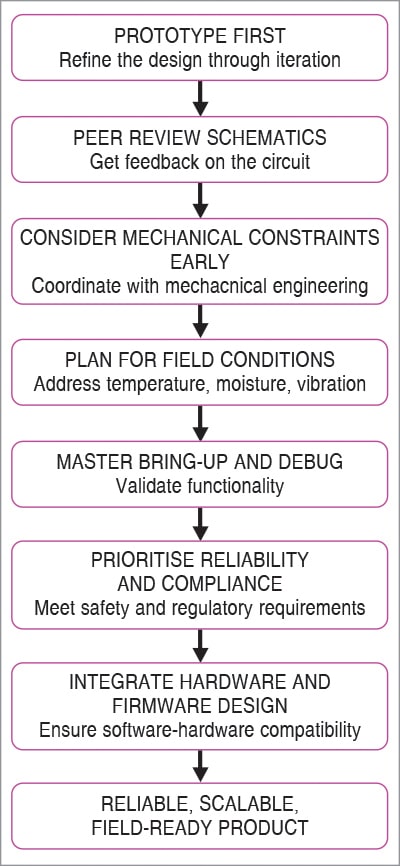

DFM is an engineering approach focused on creating electronic products that are optimised for manufacturing, assembly, testing, and long-term performance. By incorporating DFM principles early in the design process, engineers ensure that products are easy to manufacture at scale, maintain consistent quality, remain cost-effective, comply with relevant industry standards, and perform reliably in real-world conditions.

DFM is central to ensuring that the product moves seamlessly from concept to production. A design should not only be functional at prototype stage but also robust enough to be fabricated, assembled, and tested repeatedly and reliably.

The benefits of DFM are significant across the product lifecycle. By minimising production defects and the need for rework, DFM helps lower overall manufacturing costs. It also facilitates improved automation and scalability, enabling more efficient production processes. Additionally, DFM contributes to enhanced product quality and higher customer satisfaction, while accelerating time-to-market for new products.

India-specific DFM Challenges

India remains heavily dependent on imported components—especially semiconductors, sensors, and advanced displays. This exposes the supply chain to cost fluctuations and delays.

Manufacturing infrastructure limitations include:

PCB Fabrication

Advanced PCBs (for example, having >6 layers, fine traces) are challenging to source locally, especially for low-volume runs.

Enclosure Fabrication

Quality, low-volume enclosure manufacturing is limited, affecting startups and SMEs.

Testing Labs

Access to certified, third-party testing facilities is scarce, causing delays in validation and compliance.

Skills and ecosystem gaps include:

Design Expertise

Many engineers lack experience in DFM, compliance, and system reliability.

Academia-industry Disconnect

Curricula often lag behind industry needs, especially in applied design and compliance engineering.

Prototyping Ecosystem

The ecosystem for rapid prototyping and validation is still maturing, with long lead times and regulatory hurdles.

India has proven itself a global software powerhouse. However, many software engineers entering embedded domains are not trained in systematic hardware–software co-design. Startups and SMEs, while nimble, often lack the luxury of time or structured mentorship.

As a result, firmware engineers are often pushed into projects with a “code-first” mindset—writing code without proper architecture, documentation, or planning. This approach can quickly lead to unscalable, untestable, and difficult-to-debug codebases.

Go-to-market Pressures: Hidden Risks for Startups and SMEs

EFY++ CONTENT: ACCESS TO THIS CONTENT IS FREE! BUT YOU NEED TO BE A REGISTERED USER.