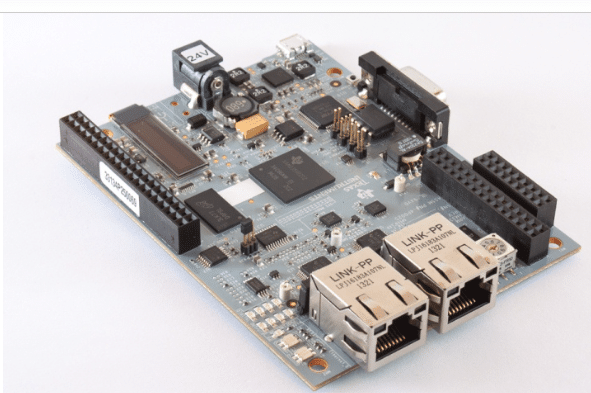

It offers engineers a complete, pre-validated platform for PROFINET IRT-compliant devices, integrating hardware, software, and real-time features to reduce development time and ensure reliable industrial network performance.

It is a critical tool for design engineers developing industrial Ethernet solutions, particularly those implementing PROFINET IRT V2.3 protocols. Industrial automation systems demand highly reliable, deterministic communication between devices, and engineers often face challenges in ensuring both real-time performance and protocol compliance.

TIDEP0029 by Texas Instruments (TI) addresses these needs by offering a pre-validated, integrated solution that combines industrial Ethernet PHYs, a PROFINET IRT switch, a PROFINET IRT stack, and application examples. By providing this comprehensive platform, the reference design significantly reduces development time, lowers risk, and accelerates time-to-market, making it an indispensable resource for engineers aiming to create robust industrial Ethernet devices.

Designed for flexibility, the design supports multiple evaluation modules, including the TMDSICE3359 and TMDXICE110, enabling engineers to select the hardware that best fits their application requirements. The design adheres to PROFINET conformance classes A, B, and C, ensuring compatibility with a wide range of industrial network configurations. Critical real-time features such as a 250-μs cycle time and one-step-time synchronization (PTCP) are built in, facilitating precise timing and coordination across devices. Additionally, the inclusion of eight consumer and provider protocol machines ensures efficient data exchange, while the Media Redundancy Protocol (MRP) provides network reliability and continuity, even in case of failures, which is essential in industrial environments where downtime can be costly.

It has integration of standard communication stacks, including the Molex PROFINET stack and the Interniche SNMP stack. This integration allows engineers to focus on application-specific development rather than low-level protocol implementation. Furthermore, the design is accompanied by comprehensive documentation, including detailed schematics, PCB layouts, and a complete bill of materials. These resources enable rapid customization and validation of the design, allowing engineers to adapt the reference design for specific industrial applications with confidence.

It serves as a complete, reliable, and scalable foundation for developing PROFINET IRT-compliant devices. By providing validated hardware and software components, extensive documentation, and real-time performance capabilities, it empowers engineers to develop high-performance industrial Ethernet systems efficiently. Leveraging this reference design ensures compliance with industry standards, minimizes development risks, and accelerates the journey from concept to market-ready solution, making it a vital asset for industrial automation projects.

TI has tested this reference design. It comes with a bill of materials (BOM), schematics, assembly drawing, printed circuit board (PCB) layout, and more. The company’s website has additional data about the reference design. To read more about this reference design, click here.