By replacing silicon with special inks, researchers are cutting the cost of clean energy production.

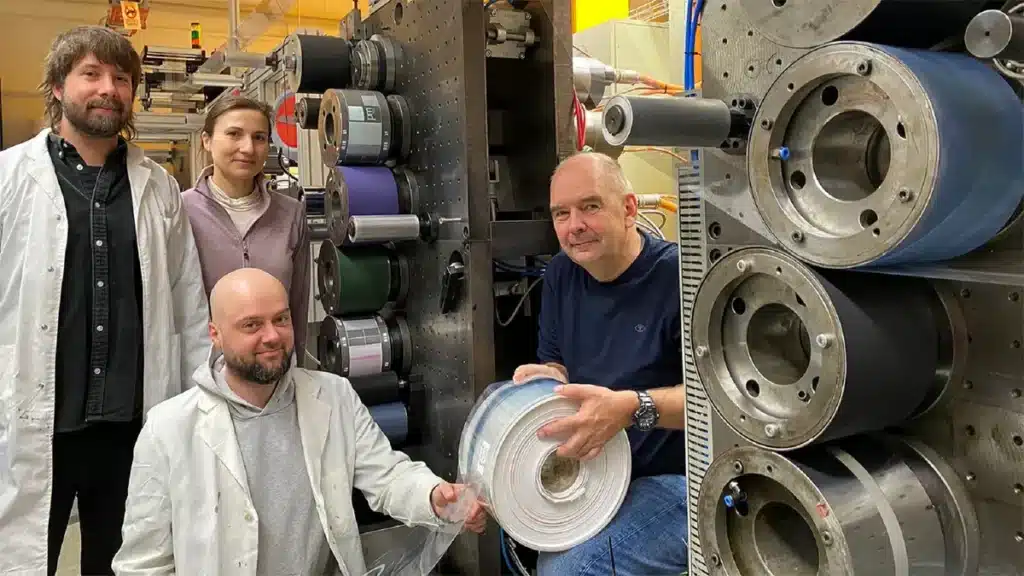

Scientists in Germany have found a new way to make solar cells similar to how newspapers are printed. The roll-to-roll printing method lets them print solar cells directly onto paper or plastic, cutting both cost and energy use. This approach could make flexible solar panels easier to produce and install on a large scale.

The research team at Chemnitz University of Technology first printed a solar cell on paper in 2011. That early version worked but had a very low efficiency of 1.7 per cent and didn’t last long.

After more than a decade of improvements, the new printed solar cells now reach 9 per cent efficiency and show much better stability. The team also reports a production success rate of over 88 per cent, showing that the process can be scaled up for mass production.

These new solar cells are made with a special polymer blend called PM6:Y12, which converts sunlight into electricity. The cells are built in several thin layers that are printed one after another using functional inks. Each ink layer has a specific electrical role. Unlike normal inks, these are not for colour but for carrying electric charge. The printing happens continuously, using large rolls of material that move through the press, much like magazine pages being printed.

Because the process runs at low temperature, it uses far less energy than the manufacturing of silicon-based solar panels, which require high heat and complex equipment. The method could make it possible to print large sheets of solar material quickly and at low cost.

This work is part of a project funded by the German Research Foundation called POPULAR. The goal is to test how long printed solar cells can last under real conditions and improve their design for future low-cost, renewable energy applications.